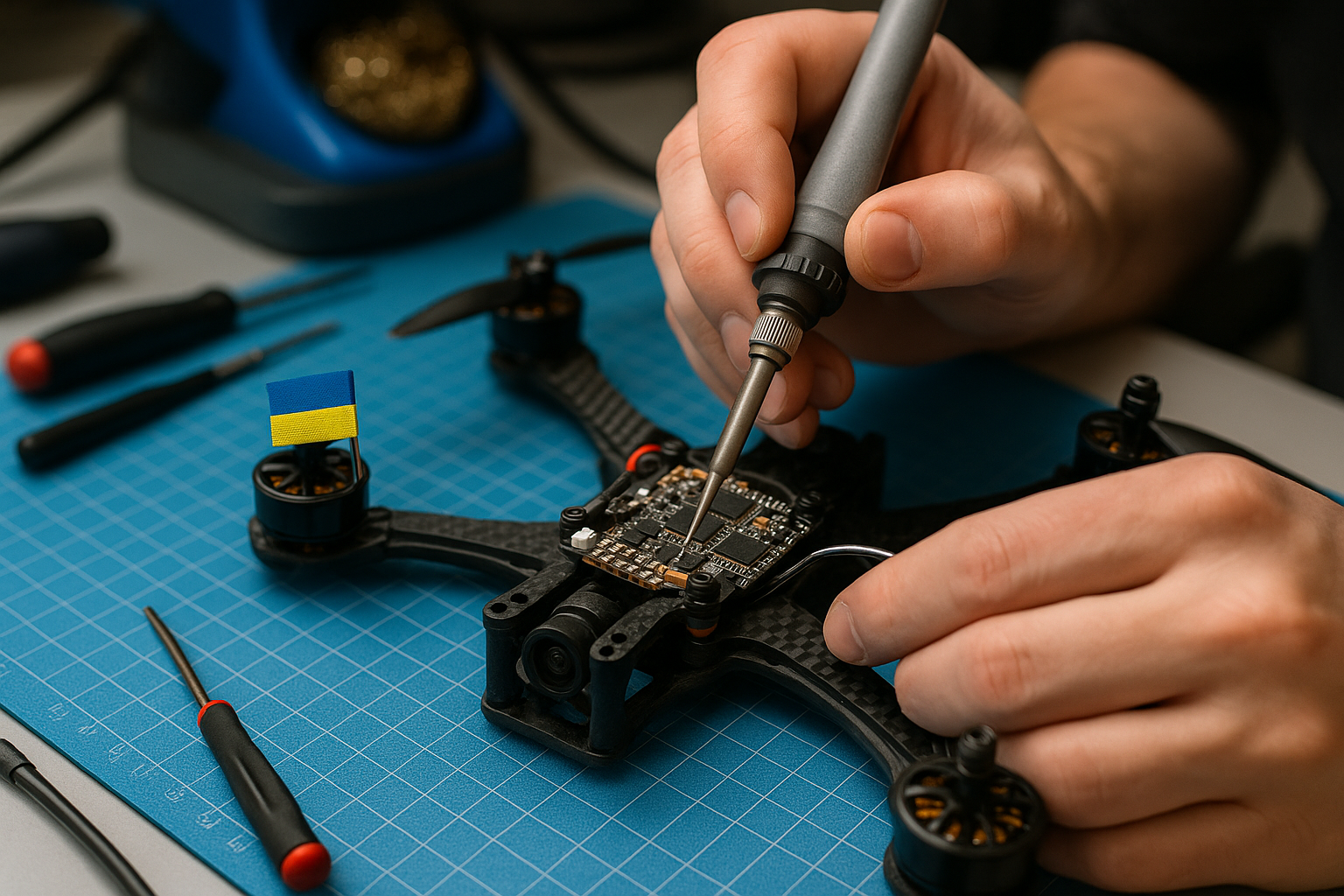

Main Components of FPV Drones

FPV drones are a type of unmanned aerial vehicle (UAV) controlled through a first-person view (FPV) system — meaning the operator sees exactly what the drone’s camera sees in real time.

Before examining how dependent Ukraine is on foreign manufacturers, it’s worth understanding what the core components of an FPV drone are.

At the heart of its design is the frame — usually made of carbon fiber. It’s lightweight yet incredibly strong, providing the perfect balance between weight, maneuverability, and durability.

The most technologically complex part of an FPV drone is the flight controller — the true “brain” of the system. It coordinates the operation of all sensors and motors, ensuring stability, responsiveness to the pilot’s commands, and overall control.

While components like the camera or radio communication systems can be relatively universal, flight controllers are drone-specific and run on specialized chips. The degree to which these chips are produced domestically is a key indicator of Ukraine’s technological independence from external suppliers.

The flight controller interacts with the motors and propellers, which generate thrust and determine speed, through electronic speed controllers (ESCs). These ESCs transmit precise signals from the controller to the motors, allowing for smooth and efficient adjustments to propeller rotation.

The power source of an FPV drone is the battery, most commonly a lithium-polymer (Li-Po) unit. It combines high capacity with relatively low weight, allowing the drone to operate longer without overloading its structure.

A separate area of importance is the set of sensors responsible for maintaining flight stability. The accelerometer measures the drone’s acceleration along three spatial axes (X, Y, and Z). It detects even the smallest jolts, vibrations, or maneuvers, helping determine how the drone’s speed and position are changing.

Working together with the gyroscope, which measures angular position changes, the accelerometer provides the flight controller with precise data needed to stabilize the drone in real time.

Modern drones are equipped with miniaturized chips that integrate these sensors into a single module — and the accuracy of these tiny components directly determines how confidently and steadily the drone can hold its position in the air.

Additional systems, such as the GPS module, are used for spatial orientation, recording the takeoff point, and following preset routes.

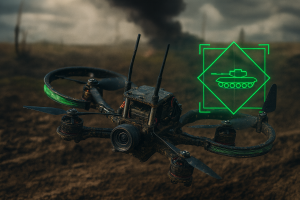

The camera serves as the drone’s “eyes,” transmitting real-time video to the pilot’s FPV goggles or monitor. The signal transmitter and receiver ensure reliable radio communication between the pilot and the drone — their quality determines the drone’s range, control precision, and resistance to electronic warfare (EW) interference.

As for the landing gear, in combat FPV drones it is typically quite simple — just a few support “legs” or plates made of carbon fiber or plastic. The main frame provides structural rigidity, while the landing gear merely cushions landings and protects the camera or explosive payload from damage.

Which Components Are Produced in Ukraine?

By the fourth year of the full-scale war, Ukraine had developed its own domestic market for drone components. As Igor Fedirko, Executive Director of the Ukrainian Arms Council, told NV in March 2025, Ukrainian manufacturers are now producing not only frames, propellers, and flight controllers, but also more technologically advanced components — including optics and even thermal imaging modules.

“About a year ago, I probably held my first electric motor for FPV drones. There were two models, and they had quite a long list of flaws. But now, almost a year later, we are talking about a product that works reliably and is being purchased on a large scale — meaning it is being mass-produced,” says Igor Fedirko.

At the same time, according to Fedirko, the level of localization remains partial. Ukrainian manufacturers often rely on imported magnets, sensors, and other microcomponents. Nevertheless, the emergence of a domestic components market has already significantly shortened logistics chains and made military drones less dependent on foreign supplies.

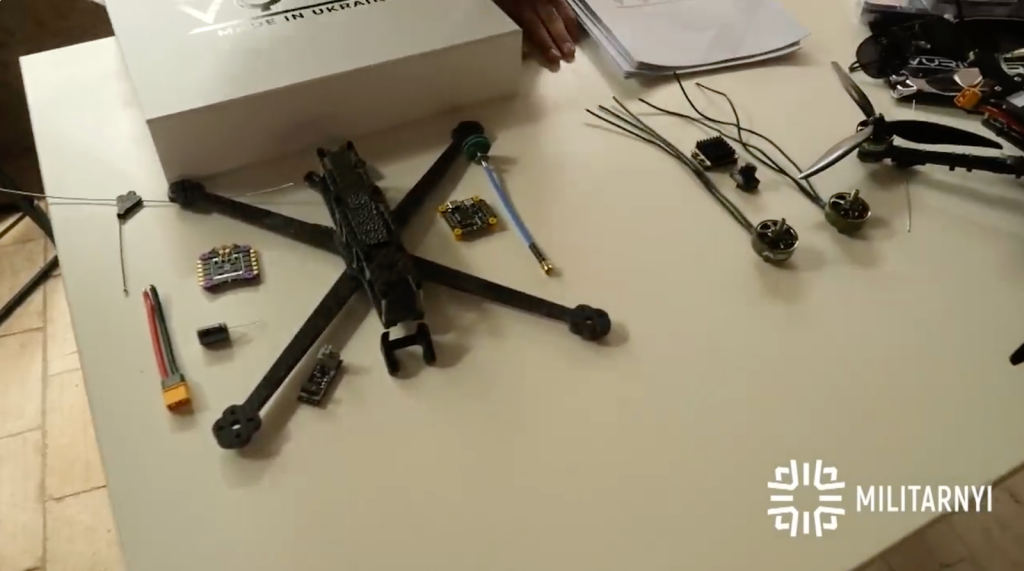

Vyriy Drone: The First Serial Batch of Fully Ukrainian FPV Drones

One example of successful localization is the company VYRIY DRONE. While it initially sourced all components from China, by 2024 around 70% of the parts for its FPV drones were produced in Ukraine. By March 2025, VYRIY DRONE announced a batch of FPV drones with 100% of components made in Ukraine.

Photo by: “Економічна правда”.

These drones, equipped with thermal imaging cameras, were produced on order for the “Army of Drones.” Thanks to serial production, Vyriy managed to bring the cost of a fully localized model down to the level of comparable drones built with Chinese components — around 30,000 UAH per unit. According to company representatives, full localization not only didn’t raise the price, but also allowed better quality control and shortened the logistics chain, making Ukrainian production more resilient to external risks.

Vyriy Drone manufactures some components in-house and sources others through Ukrainian contractors. Specifically:

- Frames, initiation boards, flight controllers, and radio control systems are produced by Vyriy itself.

- Video transmitters are developed by the Ukrainian company DEC-1.

- Motors are produced by Realgold LLC.

- Cameras are created by Odd Systems.

Additionally, the drones are fitted with a Ukrainian guidance system developed by the VGI‑9 team, which improves strike accuracy and allows them to operate more effectively even under heavy electronic‑warfare conditions.

Precision, not just range, is becoming the defining factor of drone effectiveness. How advanced targeting systems address this challenge is examined in a separate interview with the VGI-9 CTO on Revolutionizing Drone Targeting in Combat.

Earlier, in an interview, co‑founder Oleksii Babenko emphasized that localizing production is a step toward technological independence. He said that until recently only the motors, video transmitters, and cameras were still sourced from China — but by spring 2025 the company had produced its first 1,000 FPV drones made entirely from Ukrainian components.

“Wild Hornets”: Ukrainian Flight Controller and Domestically Made Combat Drones

“Wild Hornets” is a Ukrainian MilTech company founded in 2023. It develops combat FPV drones for the Armed Forces of Ukraine and also builds ground control stations, systems for remote mining, aerial bombardment, and airborne logistics. The company works closely with elite units of the Ukrainian military, and its drones are already actively used at the front.

A real breakthrough for Ukraine’s components market was that “Wild Hornets” were the first to localize production of flight controllers — the complex “brains” of FPV drones that stabilize flight and coordinate motor operation. That allowed them to reduce dependence on Chinese suppliers and cut production costs by almost 12%.

“Wild Hornets” FPV drones are fitted with Ukrainian-made carbon frames, electronic speed controllers (ESCs), propellers, sensor modules, control boards, and lithium‑polymer batteries. They also use FPV cameras that provide either analog or thermal imaging (for example, Caddx), 2.5 W video transmitters (VTX), and — in the Wally models — night‑vision systems.

Some series include the company’s own onboard computers, radio modules, and a digital Hornet Vision system that ensure precise and stable control.

Among the company’s flagships is the “Queen of the Hornets”, the largest Ukrainian FPV drone, built from 65% domestic components. It can carry up to 9.5 kg of payload and perform as a bomber, reconnaissance platform, relay, or logistics drone.

Localizing critical components remains Wild Hornets’ primary goal — the company is gradually shifting to fully Ukrainian production (frames, electronic speed controllers, batteries, onboard computers, sensors), leaving only some electronics, cameras, and motors to be imported.

Escadrone: Large-Scale Production and In-House Components

Escadrone, which began production in 2022, is now one of the leaders of Ukraine’s FPV drone market. The company not only assembles drones but also manufactures their components — from batteries and thermal-imaging cameras to high-power motors.

Photo: Escadrone

Escadrone operates a full production cycle and supplies drones directly to the front. The company is known for its high-quality assembly and a wide range of thoroughly tested models.

TAF Industries: From Mass Production to Innovation

Another Ukrainian miltech company worth mentioning is TAF Industries (formerly TAF Drones). The company operates 20 production sites and manufactures up to 80,000 drones per month.

Today, TAF is moving from pure mass production toward high-tech solutions: it is developing

- radio modules resistant to electronic warfare,

- machine-vision systems,

- Last Mile guidance modules for precision targeting,

- and AI systems for loitering munitions (kamikaze drones).

Thanks to large-scale production and major contracts, the company earned about $1 billion in revenue in 2024 without attracting external investment. 60–80% of its revenue comes from importing components and selling them — a clear indication of the massive scope of its work with drone parts.

A significant share of the company’s components is sourced from China, as this remains both logistically and financially advantageous. According to the company’s founder, Oleksandr Yakovenko, delivery from China takes only about a week longer than delivery within Ukraine. Yakovenko acknowledges the risks associated with export controls, but he points out that they are still lower than the risks of manufacturing in Ukraine under constant shelling. As an example, he mentions a recently destroyed SMT electronics-assembly line in Mukachevo.

“We assemble high-quality products from ready-made components and refine them — sometimes at the software level, sometimes at the hardware level. At the same time, the country still lacks the basic technological capability to create products entirely from scratch, the way Antonov Design Bureau or Pivdenne once did,” Yakovenko explains.

He concludes that, for now, TAF Industries cannot fully break away from China.

General Chereshnia: Serial FPV Production with Partial Localization

One of Ukraine’s active FPV-drone manufacturers is General Chereshnia. The company is known for its large production volumes — over 50,000 drones per month.

At present, it’s confirmed that their drones include both imported components (DJI cameras, SpeedyBee flight controllers, BrotherHobby/EMAX motors, AKK/Foxeer video transmitters) and partially Ukrainian-made parts, such as frame elements, connection systems, and several types of circuit boards.

Approximately 30–40% of the components are already produced in Ukraine, and this share is gradually increasing. The company is actively working to expand the proportion of locally made parts in order to reduce dependence on imports. However, a complete transition to fully Ukrainian components has not yet been achieved due to limited domestic manufacturing capacity.

Optimizing logistics and production makes the company’s drones more resilient to external risks and allows for stricter quality control.

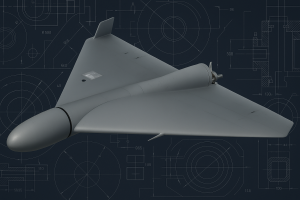

Fiber-Optic Independence

It is also worth mentioning fiber-optic FPV drones. They are immune to electronic warfare, since the connection between the operator and the drone is not maintained via radio but through a thin fiber-optic cable that unwinds during flight.

The Ukrainian company 3DTech has announced the first serially produced 30-km fiber-optic spool manufactured in Ukraine for fiber-optic FPV drones. These new spools are intended to address the current limitation where most serial models offer a range of no more than 20 km.

As electronic warfare intensifies, fiber-optic FPV drones are gaining strategic importance due to their immunity to jamming. A deeper analysis of this technology and its battlefield implications is available in “Why Fiber-Optic Drones Could Tip the Balance in the Ukraine–Russian War.”

The company’s CEO, Oleksii Zhulinskyi, emphasized that fully localizing spool production and winding in Ukraine enables strict quality control at every stage, significantly reducing cable breakage during operation. This directly addresses the factory defects often found in Chinese-made spools.

Five models of 3DTech’s “Khizhak REBOFF” fiber-optic FPV drones — offering ranges of 10–20 km — have already passed testing and received their own identification codes.

Other developers, such as Madjar’s Birds, are also known for their long-range fiber-optic FPV drones, one of which reportedly achieves a range of 41 km, though likely using imported spools.

“Ukrainian Mavic”: the Path Toward Replacing Chinese Drones

While Ukraine has successfully established mass production of FPV kamikaze drones and naval unmanned systems, one category remained outside domestic manufacturing for a long time — Mavic‑type quadcopters from the Chinese company DJI, which have become indispensable “eyes” for infantry units.

However, after the full‑scale invasion began, DJI halted official deliveries to Ukraine, forcing the country to purchase these drones through intermediaries.

Several alternatives have now appeared in Ukraine:

- Shmavic by Reactive Drone

- Yautja by Rise Technologies

- Ukropter and other models

These drones are larger than the DJI Mavic, offer better resistance to signal interference, have extended flight ranges, and are designed for more missions — up to 300 flights compared to 60 for DJI drones.

A key question remains: how truly “Ukrainian” are these drones? As Forbes notes, some manufacturers still rely heavily on imported, particularly Chinese, components, since high-quality parts like cameras are difficult to source elsewhere.

An example of successful localization is the company Frontline, which claims that only 15% of the components in their drones come from China.

Across the entire Ukrainian UAV ecosystem — including FPV drones — a separate localization process is underway. For instance, Motor-G produces over 100,000 motors per month, gradually reducing overall dependence on imported critical components for all types of unmanned aerial systems.

Which Components Are the Most Difficult to Produce for FPV Drones in Ukraine?

Despite significant progress, some components remain technologically challenging for local production. The greatest difficulties are with flight controllers, motors, video transmitters, and cameras.

The flight controller is essentially the drone’s “brain.” Manufacturing it requires high-precision microelectronics, quality printed circuit boards, and programmable chips — all of which demand certified equipment, clean-room facilities, and highly skilled engineers.

Motors are still mostly imported from China. Their production requires specialized winding machines and rotor-balancing equipment. A similar situation exists with video transmitters and cameras, which contain optical elements and microelectronics that require precise calibration and testing.

Ukrainian developers can already produce fully functional FPV drones, but complete autonomy is not yet achievable. Today, the main challenge is not only scaling up production, but also building a domestic microelectronics base, without which achieving technological independence in next-generation warfare is impossible.

This means that if China were to cut off supplies of these critical microcomponents tomorrow, Ukraine’s mass production of FPV drones would be significantly disrupted. Fully replacing the microelectronics base — which requires clean-room manufacturing and massive investment — remains a strategic challenge for years to come.

Ukrainian manufacturers are already proving that they are not just an alternative, but in many cases a higher-quality solution for the front lines. The key advantage of localization lies in quality control and optimization for military conditions.

Contact us to get detailed information about the VGI-9 drone guidance system.

Follow our updates on social media and YouTube – there you will find:

✅ Exclusive materials on the development, testing, and combat use.

✅ Useful analytical content on the war and the role of FPV drones in modern combat operations.

✅ The latest news and insights from the world of military technologies.F

📌 Join us:

🔗 YouTube: VGI-9 on YouTube

📸 Instagram: We are on Instagram

🎯 TikTok: We are on TikTok